If innovation was not part of our DNA, Safilin would not be what it is today. We know that if a company does not move forwards, it will go backwards, and have kept this in mind for over 200 years. Our research activity is based on three major pillars: We are attentive. We anticipate. And we develop partnerships.

FLAX REINFORCEMENTS FOR COMPOSITES

Linen: A force of nature.

Safilin is an active participant in the flax textile reinforcement market for biocomposite production.

The result of 10 years of R&D in the Flax Lab: our range of rovings operates and maximises Safilin’s “Low Twist” technology to produce 100% flax roving, a fibre with exceptional properties.

Our Research and Development Laboratory is constantly conducting investigations into flax fibres with unique properties, such as fibres for reinforcing composites.

These materials are used in technical applications across many sectors

TRANSPORT

CONSTRUCTION

WIND ENERGY

sport and leisure

FURNITURE

MUSIC

OUR PRODUCTS

These materials are used in technical applications and composite with high mechanical performance for the automotive industry, sport and leisure, construction, aviation and rail transport, consumption goods and design…

ROVING

Low Twist Roving Tex200

Low Twist Roving Tex400

Low Twist Roving Tex1000

Low Twist Roving Tex2000

TEXTILE REINFORCEMENT

Fabrics for resin finishing

Based on our Low Twist Roving Tex400:

- Plain 500g/m2

- Twill 2/2 500g/m2

Based on our Tex200- and Tex400-wrapped Low Twist Rovings:

- Unidirectional 150g/m2

- Plain 250g/m2

- Twill 2/2 250g/m2

- Plain 500g/m2

- Twill 2/2 500g/m2

PROPERTIES

TECHNICAL ASPECTS

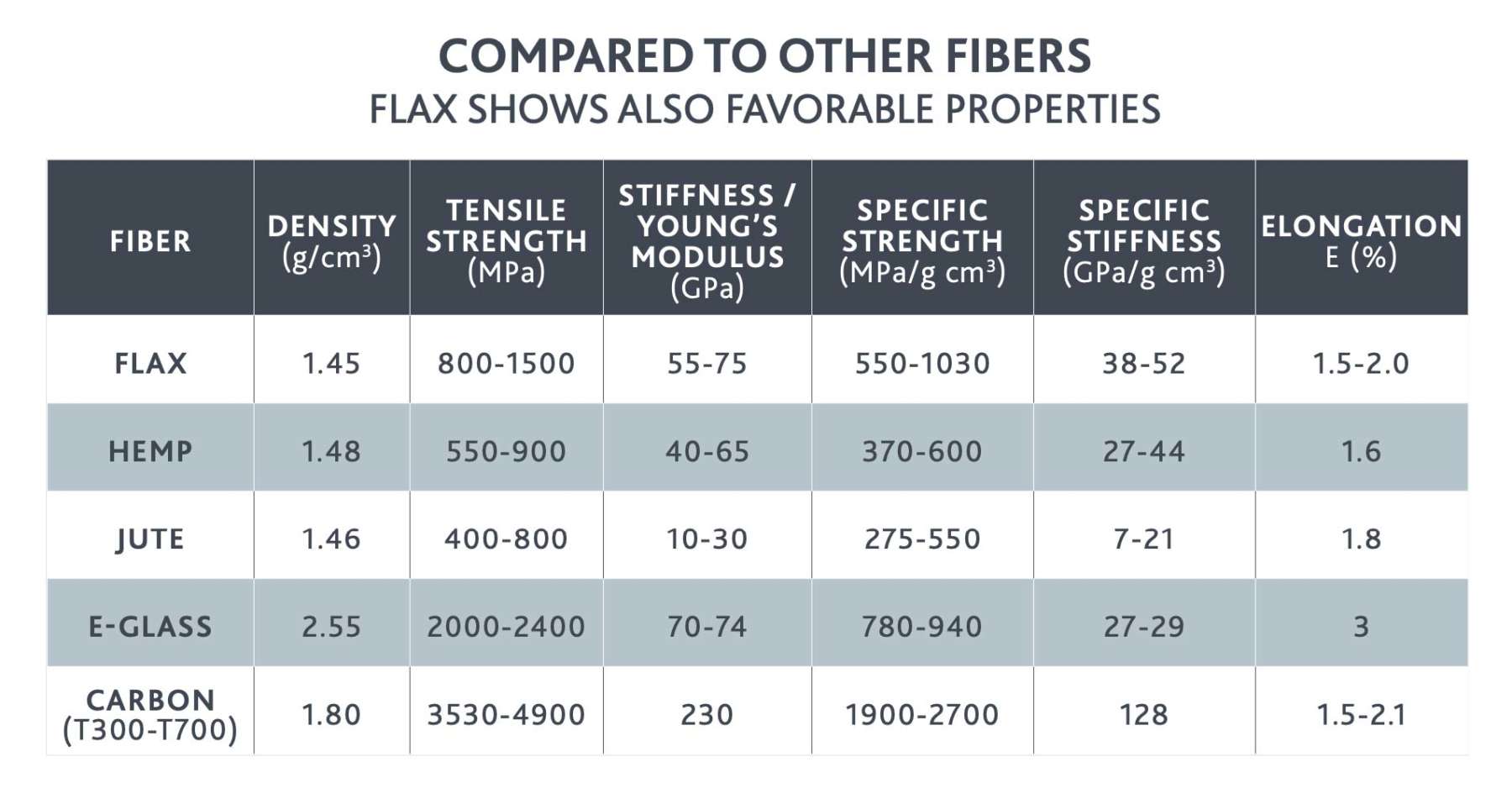

LOW DENSITY

-40% less than fibreglass

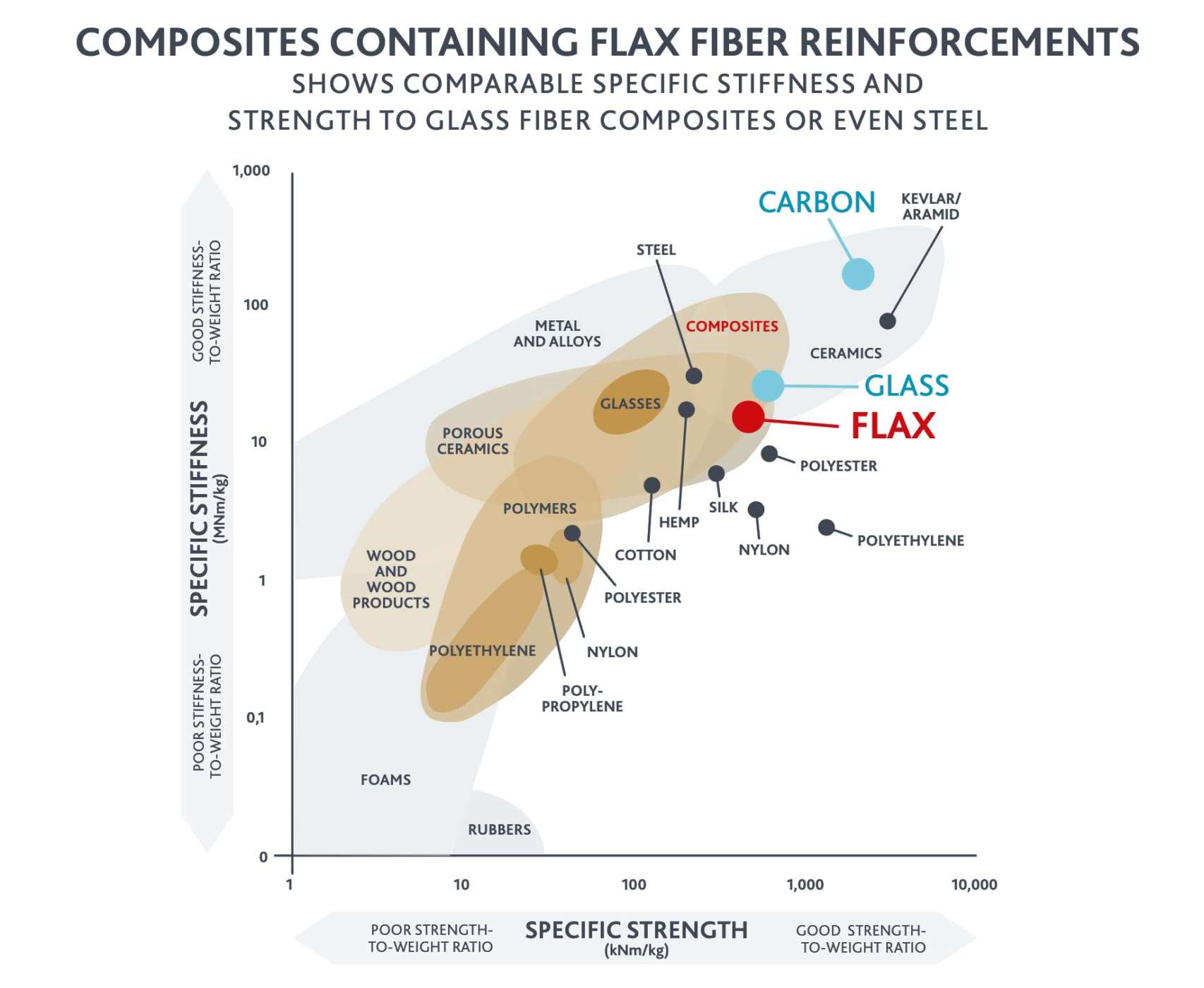

HIGH SPECIFIC STIFFNESS AND RESISTANCE

Up to 30% more specific stiffness than glass.

FLEXION PROPERTIES

French flax has unique flexion properties compared with glass and carbon reinforced composites: greater flexion hence less likely to break.

VIBRATION DAMPING

Up to twice as absorbent as glass and three times as absorbent as carbon*.

* based on the result of flax epoxy composite exposed to frequency of 1 Hz at 25°C

THERMAL INSULATION

15 to 30% better insulation compared to glass.

SOUNDPROOFING

Up to 15% better absorption compared to glass*.

* based on flax epoxy composite

RADIOWAVE TRANSPARENCY

15% less permittivity for 17% signal attenuation and 10% more velocity than glass composites.

PROCESS

- Compatible with technical textile and composite processing

- Drapability

- Harmless for working health

- Reduced wear on machining and production tools

- Very low impact on the environment

- 100% biodegradable linen yarn

- New design aspect

OUR R&D LABORATORY

We have many projects underway at our Flax Lab: internally with the constant improvement and development of our products; and in partnership with the automotive, rail and wind turbine industries, just to mention a few.

EXEMPLARY PROJECTS

CULTURE IN: FLAX FIBRE SERVING INTERIOR DESIGN!

We are partners with the company CULTURE IN, a French startup which created VARIAN®.

Between texture and structure, VARIAN® is a rigid impregnated fabric which is customisable, easy and ready to use, and entirely bio-based. A real textile sheet made of flax, it combines technical sophistication and aesthetics for the eco-design, layout and decoration of healthy and elegant living spaces.

VARIAN® meets the requirements of the industrial sector, combining comfort and technical performance with respect for the environment for living spaces for boats, planes and trains.

THE KAIROS PROJECT: FLAX FIBRES SERVING THE BOAT INDUSTRY

Safilin is also part of the adventure led by KAIROS, designer of the Gwalaz concept boat.

KAIROS worked closely with the TRICAT shipyard to build the 23.5 model, launched on 28 May 2013. Laboratory tests with IFREMER Brest, supported by the University of Bretagne Sud, confirmed the possibility to replace standard composites such as fibreglass and PVC core with biobased materials, such as flax fibres, cork, balsa wood and a resin containing 30% plant molecules.

The region of Brittany funded the unique prototype as part of its eco-innovation programme. Gwalaz was used by the Breton Lost in the Swell team. After this, Barravel and Des Ile Usions, Ronan Gladu, Aurélien Jacob and Ewenn Le Goff navigated from island to island exploring new waves, the coastline and meeting local residents.

In 2017, Gwalaz was modified for the addition of the prototype of an innovative propulsion wing for the reduction of fuel by transport craft.

Discover our know-how

Learn about every step, from the selection of the best fibres and blending to traceability and a storage service.