History of Safilin

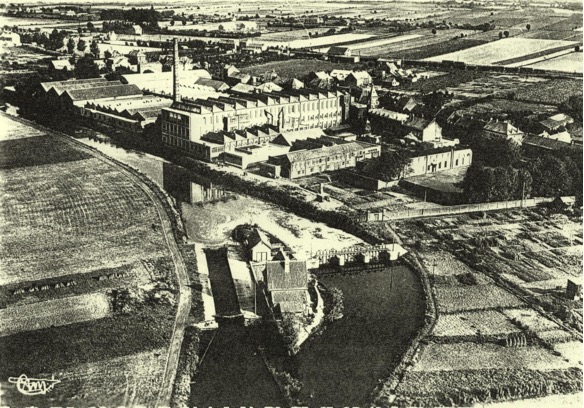

The history of Safilin began more than 250 years ago in our original cradle, the Hauts-de-France. Originally, Safilin owned several weaving mills, garment factories and spinning mills. In the 1950s, we refocused our activities on spinning. In the 1990s, we decided to relocate our factories to Poland, a country with strong flax production traditions, in order to pursue our activities.

Project Origin

Flax is the only plant material in France that can be 100% processed. In fact, 80% of the world’s flax production is grown in Europe and more than 60% of this production is cultivated in France. 90% of this production, however, is shipped abroad to be transformed into yarn, fabric or finished products. Nevertheless, in Europe we now have the possibility of carrying out all the processing stages. In France, there was just one missing link… the spinning process.

This is why, in response to an increasing demand for greater traceability, transparency and locality on the part of both consumers and textile industry players, 1.5 years ago we decided to re-establish a linen spinning mill in Béthune, in our historical cradle.

Setting Up the linen Spinning Mill

The process of setting up the spinning mill was divided into several stages :

- Finding a suitable building to set up the spinning mill. We wanted to set up our spinning mill in the proximity of our subcontractors and our head office in Sailly-Sur-La-Lys. That is why we opted for Béthune.

- Renovating the building to ensure its compliance with current standards as well as with our manufacturing process.

- In the meantime, we began recruiting our future employees.

- Organising the relocation of the tools necessary to furnish the spinning mill. Rather than buying new machines, in the interest of environmental responsibility, we chose to bring back the tools that we had previously used in our factories in Poland.

- Setting up the spinning tools and organising the different workshops within the spinning mill. We could rely on the precious help of our Polish associates who came to train and help our new French collaborators.

- Our French spinning mill offers two technologies, both of which we had previously used in Poland: Dry and wet spinning.

- First 100% French yarn spools as of March 2022

Support

We have been lucky enough to be supported in this project by the public authorities through a variety of organisations:

- The French government, with the ‘France Relance’ programme

- The Hauts-de-France region

- The Béthune Bruay agglomeration community

Our Flax Spinning Mill

The flax fibre used in our French yarn will be exclusively French

Our offer will consist of two segments:

- Wet spinning: nm 26, our standard yarn for textile products such as household linen and clothing

- Dry spinning: nm 2.6 and nm 6 plus for the furniture market

These yarns will be available for delivery as of June 2022.

In order to keep up with the ever increasing demand, we aim to have an annual production capacity of 350 tonnes. To produce this quantity, we are going to hire approximately 50 employees.

It is a source of great pride for the Safilin teams to be able to re-open a spinning mill in France, our home region. The continuity of the know-how and its transmission are values that drive us on a daily basis, this flax spinning mill being the reflection of these values.